Description

We provide state-of-the-art monitoring and measurement solutions for compressed air systems, enabling accurate performance evaluation, leak detection, and energy optimization. Our complete Compressed Air Audit System combines precision instruments with advanced analytics to ensure your system runs at maximum efficiency.

Our Solutions Include:

- Air Flow Meters (For Wet and Dry Air)

- Accurate measurement of compressed air consumption (m³/min, CFM).

- Thermal mass or differential pressure technology for high accuracy.

- Ideal for identifying inefficient usage and optimizing system capacity.

- Pressure Gauges & Digital Transmitters

- Real-time monitoring of operating pressures.

- Helps maintain optimal compressor setpoints for energy savings.

- Detects pressure drops in the distribution network.

- Dew Point Monitoring Systems

- Continuous tracking of compressed air moisture levels.

- Ensures air quality compliance (ISO 8573-1 standards).

- Prevents costly damage to pneumatic tools and processes.

Benefits of a Complete Compressed Air Audit:

- Energy Savings – Identify and eliminate leaks or pressure losses.

- Process Reliability – Maintain optimal air quality and pressure for consistent production.

- Compliance – Meet industry air quality standards for food, pharma, and critical applications.

- Cost Reduction – Reduce compressor running hours and maintenance costs.

Leak Detection Services:

Our ultrasonic and thermal imaging tools can locate even the smallest leaks in your compressed air system, helping you prevent wastage and improve overall efficiency.

Whether you operate in manufacturing, food & beverage, pharmaceuticals, or heavy industry, our integrated monitoring systems deliver precise insights to keep your compressed air network performing at its best.

📊 Types of Compressed Air Flow Meters

- Thermal Mass Flow Meters

- Measures mass flow directly using heat transfer principles.

- Ideal for low-pressure drop applications and varying flow rates.

- Differential Pressure (DP) Flow Meters

- Uses an orifice plate, Venturi tube, or Pitot tube to measure flow.

- Simple, robust, and suitable for high-pressure air systems.

- Vortex Shedding Flow Meters

- Measures vortices created by an obstruction in the airflow.

- Suitable for both wet and dry compressed air.

- Ultrasonic Flow Meters

- Non-invasive clamp-on sensors; measure flow using sound waves.

- Can be installed without cutting pipes; ideal for retrofit applications.

- Variable Area Flow Meters (Rotameters)

- Uses a float in a tapered tube to indicate flow rate.

- Common for visual indication and simple setups.

- Coriolis Mass Flow Meters

- Directly measures mass flow and density.

- Very accurate but typically more expensive.

🔍 Types of Compressed Air Leak Detection Systems

- Ultrasonic Leak Detectors

- Detects high-frequency sound waves from air leaks.

- Portable and suitable for preventive maintenance programs.

- Thermal Imaging Cameras

- Detects temperature changes caused by escaping compressed air.

- Useful for identifying hidden leaks in large facilities.

- Acoustic Camera Leak Detection Systems

- Combines ultrasonic sensors with visual imaging to pinpoint leak locations in real time.

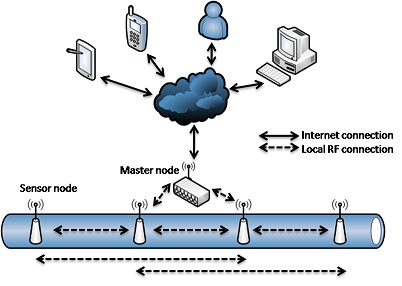

- Permanent Leak Monitoring Systems

- Fixed sensors installed in compressed air pipelines for continuous leak detection.

- Sends alerts via software or IoT systems.

- Pressure Decay Testing

- Measures system pressure drop over time to detect overall leakage rate.

-

-

Leak Detection System Type Working Principle Advantages Best Application Ultrasonic Leak Detector Detects high-frequency sound from escaping compressed air. Portable, quick leak detection. Preventive maintenance, plant surveys. Thermal Imaging Camera Detects temperature differences caused by escaping air. Non-contact, easy to use. Locating leaks in insulated or hidden lines. Acoustic Camera Leak Detection Combines ultrasonic detection with visual imaging. Real-time pinpointing of leak location. Large facilities, noisy environments. Permanent Leak Monitoring System Fixed sensors monitor continuously and send alerts. 24/7 monitoring, integrates with IoT. Critical air systems, remote plants. Pressure Decay Testing Measures drop in pressure over time in a sealed system. Simple, no extra equipment required. System-wide leak rate measurement.

-

Type Working Principle Advantages Best Application Thermal Mass Flow Meter Measures heat dissipation caused by air flow. High accuracy, no moving parts, low pressure drop. Monitoring compressed air usage, energy audits. Differential Pressure (DP) Flow Meter Uses pressure difference across an orifice, Venturi, or Pitot tube. Robust, low cost, wide pressure range. Industrial compressed air systems with stable flow. Vortex Shedding Flow Meter Detects vortices generated by an obstruction in the airflow. Works with wet/dry air, minimal maintenance. Mixed phase air systems, process air measurement. Ultrasonic Flow Meter Uses sound waves to measure flow velocity. Non-invasive, easy to install, no pipe cutting. Retrofit systems, large diameter pipes. Variable Area Flow Meter (Rotameter) Float rises in a tapered tube based on flow rate. Simple, visual display, low cost. Local flow indication at equipment. Coriolis Mass Flow Meter Measures mass directly using Coriolis effect. Very accurate, measures density too. High precision industrial air flow monitoring. - Pressure Decay Testing

compressed air flow meter supplier Pakistan

air flow meter supplier Pakistan

pneumatic flow meter Pakistan

industrial air flow meter Pakistan

compressed air monitoring system Pakistan

compressed air consumption meter Pakistan

digital compressed air flow meter Pakistan

thermal mass air flow meter Pakistan

vortex flow meter for compressed air Pakistan

ultrasonic compressed air flow meter Pakistan

insertion type air flow meter Pakistan

inline compressed air flow meter Pakistan

portable compressed air flow meter Pakistan

low pressure air flow meter Pakistan

multi-parameter air flow meter Pakistan

compressed air flow meter for textile industry Pakistan

air flow meter for pharmaceutical Pakistan

compressed air flow meter for cement industry Pakistan

air flow monitoring system for food industry Pakistan

compressed air flow meter for automotive workshops Pakistan

industrial compressed air measurement Pakistan

compressed air flow meter supplier Karachi

compressed air flow meter supplier Lahore

air flow meter supplier Islamabad

compressed air flow meter Faisalabad

air flow monitoring system Sialkot

ISO certified compressed air flow meter supplier Pakistan

energy efficient compressed air monitoring Pakistan

calibrated compressed air flow meter Pakistan

NEQS compliant air flow meter Pakistan

industrial grade air flow meter Pakistan

best compressed air flow meter supplier in Pakistan

digital compressed air flow monitoring system Pakistan

thermal mass flow meter for compressed air Pakistan

ultrasonic compressed air flow meter installation Pakistan

industrial air flow meter with data logging Pakistan

affordable compressed air flow meter supplier Pakistan

Reviews

There are no reviews yet.