Description

Hydrogen Generation through Water Electrolytes / Water Electrolysis

Overview

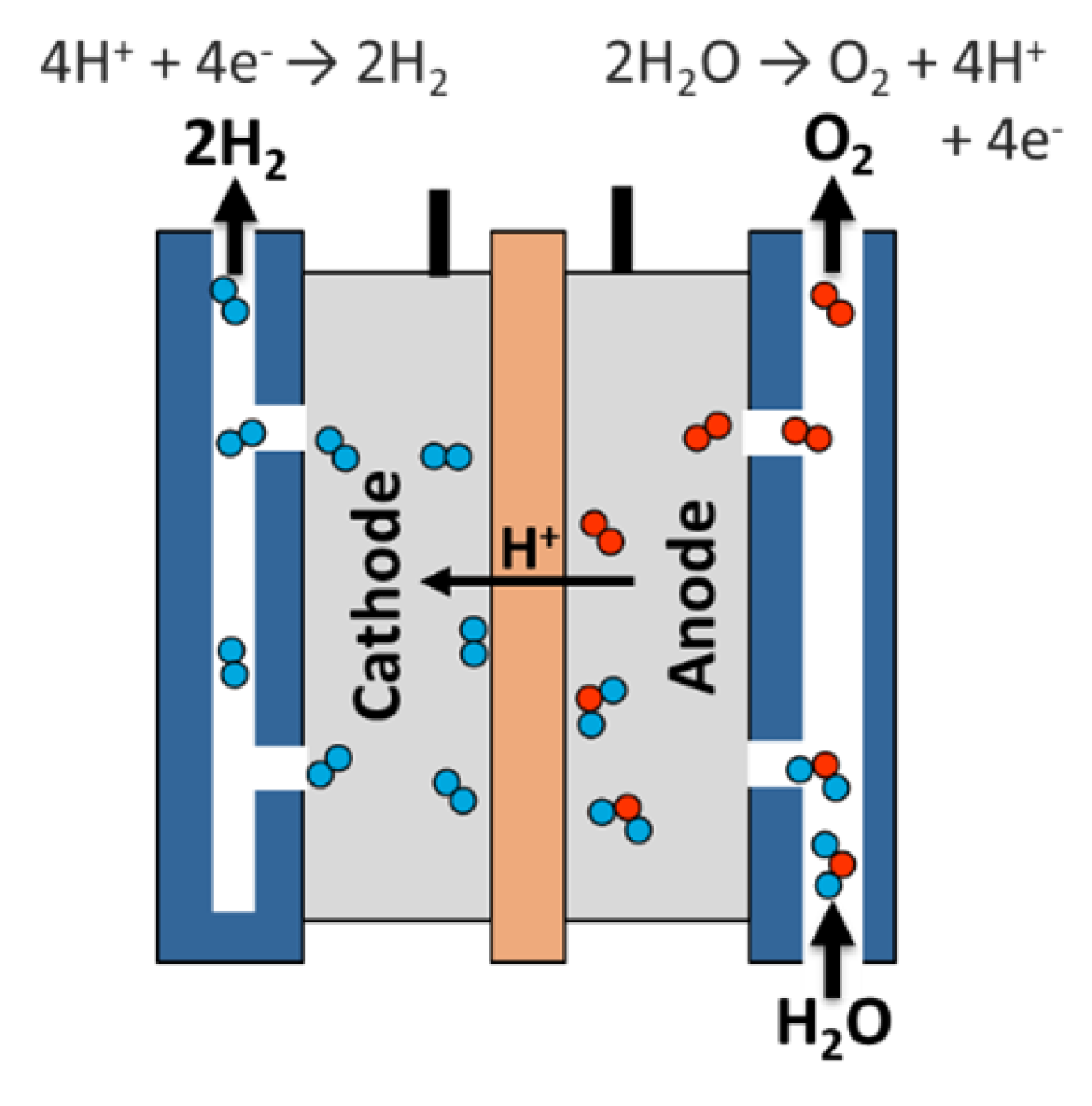

Hydrogen generation through water electrolysis is a clean and sustainable method of producing hydrogen by splitting water (H₂O) into its basic components—hydrogen (H₂) and oxygen (O₂)—using an electric current. This process eliminates the need for fossil fuels and provides high-purity hydrogen suitable for a wide range of industrial and energy applications.

Working Principle

Electrolysis takes place in an electrolyser, which consists of two electrodes (anode and cathode) submerged in water containing an electrolyte. When direct current (DC) electricity is applied:

-

At the cathode (-): Water molecules gain electrons and release hydrogen gas (H₂).

-

At the anode (+): Water molecules lose electrons and release oxygen gas (O₂).

The overall reaction is:

2H₂O (l) → 2H₂ (g) + O₂ (g)

Key Features of Hydrogen Generation via Electrolysis

-

High Purity Hydrogen: Produces hydrogen up to 99.999% purity, ideal for sensitive applications.

-

Environmentally Friendly: No carbon emissions if powered by renewable electricity (green hydrogen).

-

On-Demand Production: Hydrogen can be generated where and when it is needed, minimizing storage risks.

-

Scalability: Systems can range from small laboratory units to large industrial-scale hydrogen plants.

-

Safety: Advanced designs ensure safe handling, storage, and delivery of hydrogen and oxygen gases.

Applications

-

Industrial Use: Welding, heat treatment, hydrogenation processes, and glass manufacturing.

-

Energy Sector: Fuel cells for backup power, mobility solutions (hydrogen vehicles), and grid energy storage.

-

Electronics: Semiconductor manufacturing and cooling in power plants.

-

Laboratories & Research: High-purity hydrogen for analytical instruments and experiments.

Advantages

-

Zero greenhouse gas emissions when paired with renewable power.

-

Reduces dependency on fossil fuels.

-

Continuous and reliable hydrogen supply.

-

Meets global demand for clean energy solutions.

Hydrogen Generation through Steam Methane Reforming (SMR)

Steam Methane Reforming (SMR) is based on the controlled reaction of natural gas with high-temperature steam. When exposed to heat and a catalyst, methane (CH₄) molecules break down and combine with steam (H₂O) to produce hydrogen (H₂) and carbon monoxide (CO). The carbon monoxide doesn’t go to waste—it is further reacted with steam in what’s known as the water-gas shift reaction, producing additional hydrogen and carbon dioxide (CO₂).

Chemical Reactions:

-

CH₄ + H₂O ⇌ CO + 3H₂

-

CO + H₂O ⇌ CO₂ + H₂

This method is extremely efficient and is generally preferred for hydrogen capacities above 100 Nm³/h, delivering high output at very competitive production costs.

For medium-scale requirements (50, 100, 150 Nm³/h), compact mobile hydrogen container units are available. These containerized systems can be installed in just a few days and, if needed, relocated to a new site almost as easily as moving houseplants (though admittedly with a few more cranes). For larger demands (200 Nm³/h and beyond), a permanent on-site facility is designed and operated professionally for continuous, industrial-scale production.

Advantages of SMR Systems

-

Mobile containerized units for 50–150 Nm³/h

-

High-quality plants for 300–13,000 Nm³/h

-

Hydrogen purity up to 99.999%

-

Typical pressure: 10–30 barg

-

Fully automatic operation with remote control

-

Equipment and components from world-class suppliers

-

Factory-prefabricated skid/module designs for quick installation

-

Backed by more than 50 years of expertise

Typical Utilities for 1,000 Nm³/h Hydrogen (via SMR)

-

380–420 Nm³/h natural gas

-

900 kg/h demineralized water

-

35 kW electrical power

-

38 m³/h cooling water

| Model | Hydrogen Capacity (m³/h) | Oxygen Capacity (m³/h) | Purity % | Pressure (Bar) | Power Requirement |

|---|---|---|---|---|---|

| Mod. 0.6 | 0.4 | 0.2 | >99.5 | 1.8 bar | 230VAC / 50Hz / 1 |

| Mod. 1.6 | 1.06 | 0.54 | >99.5 | 1.8 bar | 230VAC / 50Hz / 1 |

| Mod. 3.7 | 2.47 | 1.23 | >99.5 | 1.8 bar | 400VAC / 50Hz / 3 |

| Mod. 4.2 | 2.8 | 1.4 | >99.5 | 1.8 or 4 bar | 400VAC / 50Hz / 3 |

| Mod. 6.0 | 4.0 | 2.0 | >99.5 | 1.8 or 4 bar | 400VAC / 50Hz / 3 |

| Mod. 8.0 | 5.33 | 2.67 | 99.999 | 4 bar | 400VAC / 50Hz / 3 |

| Mod. 11.0 | 7.33 | 3.67 | 99.999 | 4 or 6 bar | 400VAC / 50Hz / 3 |

| Mod. 15.0 | 10.0 | 5.0 | 99.999 | 4 or 6 bar | 400VAC / 50Hz / 3 |

| Mod. 19.0 | 12.67 | 6.33 | 99.999 | 4 or 6 bar | 400VAC / 50Hz / 3 |

| Mod. 33.0 | 22.0 | 11.0 | 99.999 | 4 or 6 bar | 400VAC / 50Hz / 3 |

| Mod. 66.0 | 44.0 | 22.0 | 99.999 | 4 or 6 bar | 400VAC / 50Hz / 3 |

| Mod. 120.0 | 80.0 | 40.0 | 99.999 | 4 or 6 bar | 400VAC / 50Hz / 3 |

Note: If required, additional equipment can be used to increase the pressure and can customize the Unit as per cliental need.

Reviews

There are no reviews yet.